SCHEFFER PIPE AND ROD TRANSPORT SOLUTIONS

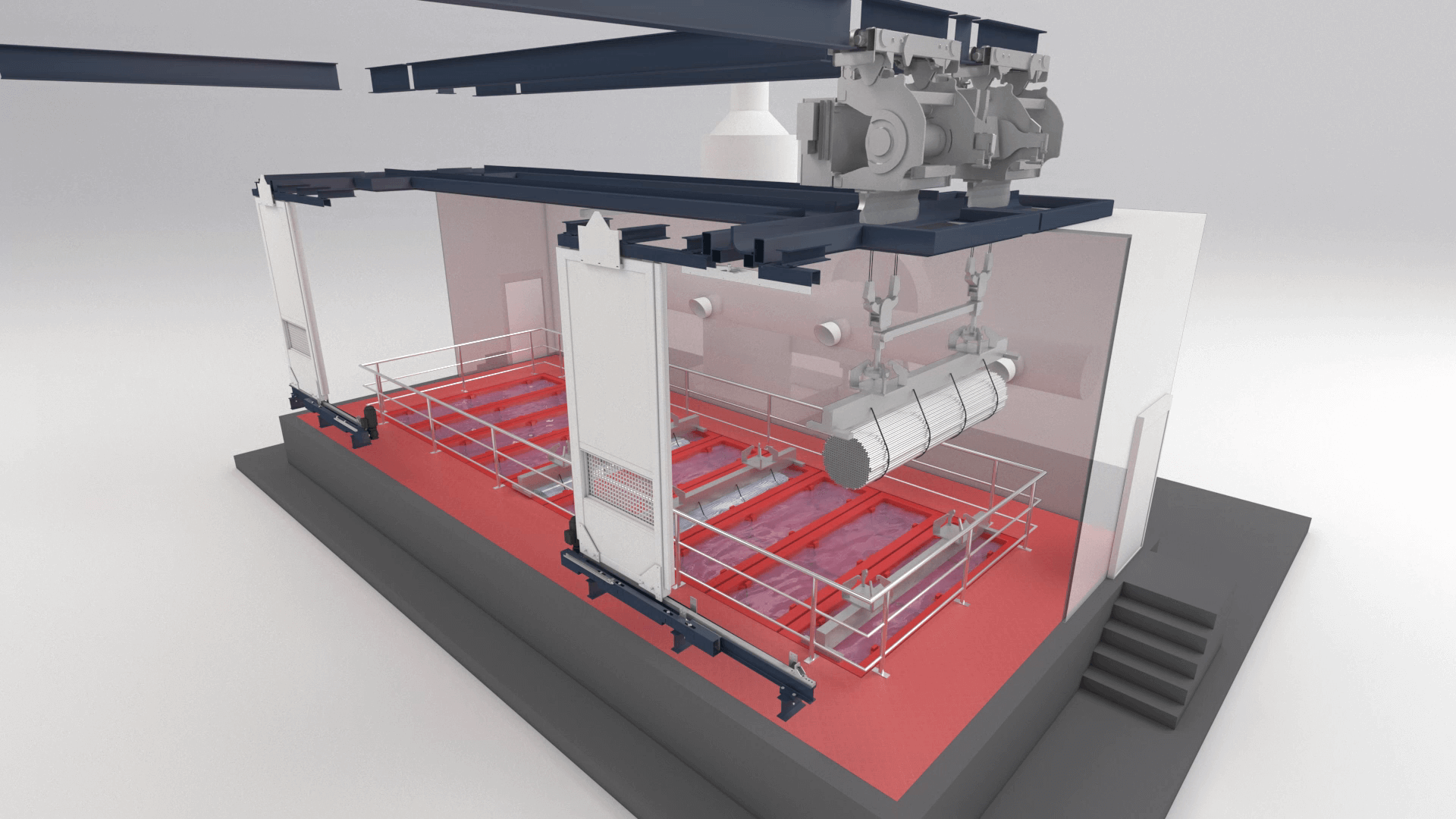

The transport of pipes/tubes and rods during the surface treatment is often complex and requires numerous processes such as oiling, degreasing, pickling, activating, phosphating, neutralizing or soaping, which must be carried out with precise specifications or according to recipes.

Depending on the chemicals used, special demands are forced on the cranes and manipulation systems. When pickling, an acidic atmosphere is created which can limit the availability of the systems and with others the carryover of the individual substances into the subsequent process steps must be avoided.

Scheffer supplies individual systems for handling tubes and rods for your application in order to achieve maximum product quality and to ensure high availability and flexibility of our system.

Depending on the application, our scope of delivery includes:

• Individual cranes including mounting systems for pipes, rods or bundles

• Floor-bound conveyor systems that enable material to be transported between individual production areas

• a tried and tested pickling line to protect our transport technology from unplanned downtimes

• A complete automatic control that is specially designed for your processes and is equipped with a prescription management system with which our customers can also adjust treatment parameters themselves

• Drip protection systems that prevent the media from being carried over into other basins

With our technology we are also able to display the process of pipe and stainless steel pickling fully automatically within an encapsulated pretreatment. We were able to adapt our technology from the world of hot-dip galvanizing plants for this process and thus gain a head start on the market. Our plant concept is therefore suitable for various types of metal treatment. These include e.g. chemical milling, pickling with hydrochloric acid, sulfuric acid or nitric acid, phosphating, soaps or reactive oils. The software for the automatic solution comes from in-house. In this way we can ensure that all customer requirements are met.

Various recipes with various parameters (for routine and special programs) can be entered on a central PC and only changed by authorized operators. This ensures consistently high quality with high flexibility at the same time.