Combining advantages

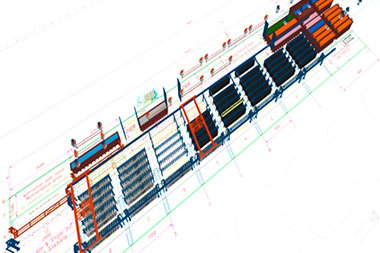

Stacking cranes – the perfect combination of a forklift truck and a bridge crane

Various types of materials handling equipment offer different advantages and disadvantages for the respective area of application. When transporting materials on the ground, forklift trucks are generally used, but these machines have significant shortcomings when it comes to occupational health and safety as well as flexibility. To minimise these drawbacks and combine them with other advantages, we designed the Scheffer stacking crane especially for our customers.

Our stacking crane combines the advantages of a forklift truck with those of a bridge crane:

- When using a stacking crane, materials can be transported above the ground, which means they can simply travel above any loads that remain on the ground and be lifted over obstacles;

- With a swivel range of 360°, only a minimum amount of movement space is required;

- As stacking cranes are extremely flexible, they can create very closely spaced storage areas;

- Stacking crane operators have a clear view of the load to be transported;

- Stacking cranes are operated by remote control, from a safe distance; This often greatly improves occupational health and safety;

- The rigid load telescope affords extremely accurate positioning and fast travel speeds;

- When used in high-bay storage systems, Scheffer stacking cranes can be automated, thereby offering maximum efficiency.

In the steel trade and in modern galvanising plants in particular, Scheffer stacking cranes are a better alternative to forklift trucks. Their decisive advantages are highlighted when loading and unloading HGVs as well as loading stations or lifting and lowering stations.