Individual components for the hot-dip galvanizing industry

Also a reliable partner for individual components

Scheffer Krantechnik is not only the perfect contact partner for new plants, but it is also customers’ first port of call when it comes to modernising or upgrading existing systems. Our product range comprises all individual components for internal jig transport. Scheffer can supply a comprehensive range of products, from start-up stations to pickling or galvanizing cranes.

Lifting and lowering stations come in a variety of technical designs. Depending on the conditions on site, they can be moved in longitudinal direction or equipped with a chain conveyor, for example. Even the lowest and highest lift positions can be flexibly adjusted to the requirements on site.

Bridge cranes are used in almost all galvanizing plants. They enable staff to optimise materials handling both within and between the different plant units. As well as transporting materials, they are also used for transporting jigs when fitted with the appropriate load-handling equipment. Bridge cranes also exist in single or double girder versions, the only difference being the number of components. As a general rule, basic bridge cranes comprise the following components: crane bridge, endcarriage pair, trolley with traction drive, hoisting unit and load-handling equipment.

Bridge cranes are commonly found in open pre-treatment and galvanizing kettle areas (a mobile galvanizing kettle enclosure is also found here). As these areas are exposed to an aggressive environment, it is vital to ensure that the design of the cranes is suitably resistant. Furthermore, all of the equipment listed below must be made of a type of steel or plastic that is resistant to hydrochloric acid. This is the only way to ensure that it functions safely, the plant has a long service life and the cranes have a minimum risk of downtime.

Some examples of necessary measures:- Special acid and/or heat-resistant coating

- Plastic switch cabinets Cable entry from below

- GRP grid covers on walkways

- Screws made of suitable materials

- All screws greased

- Screw fittings sealed with silicone

- Gear stop switch in a separate housing

- Cable trays made of stainless steel or plastic

- Almost all pipes made of neoprene

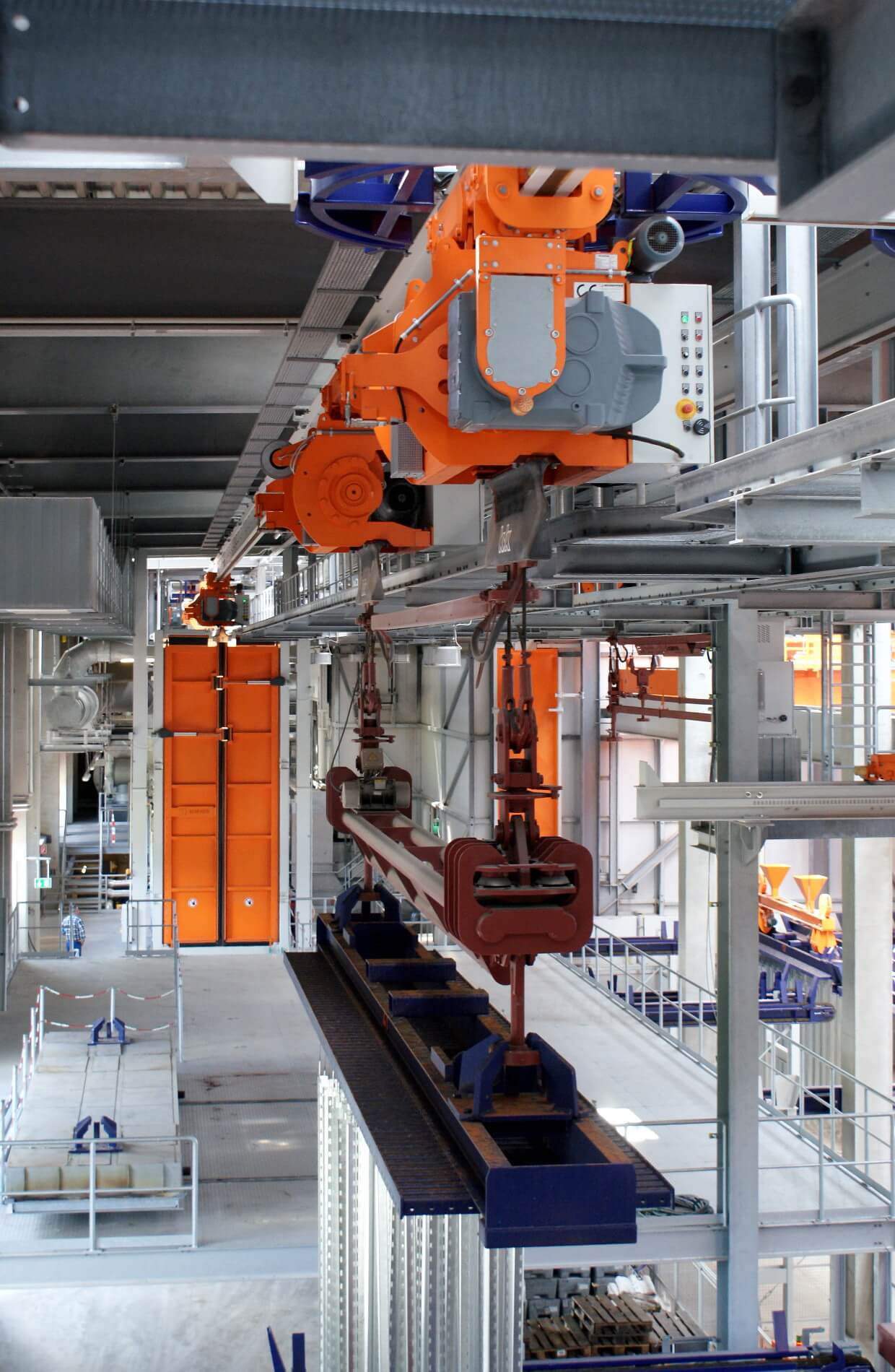

In hot dip galvanizing, distribution cranes fulfill a variety of tasks. For example, they supply setup stations and manage the traverse memory. In order to minimize idle times at set-up stations, distribution cranes are equipped with two stations, so that simultaneous transport of full and empty crossbeams can take place.

Our experience - Your advantage:

- Fast truss change due to the parallel recording of empty and full traverses

- Fast and safe load handling

- Simultaneous crane and trolley travel (diagonal travel) and thus optimized trussing

- High full load hours (3m) with high lifting speed

- Maximum operating and safety at work

- High availability

- 100% duty cycle

- Low wear

Driving units consist of two parallel, coupled cranes. Highly flexible drive units cover a number of plant areas with one interconnected transport system.

Our experience - Your advantage:

- Fast and safe load handling

- Little rope deflection

- Low number of moving components in the rope drive

- High full load hours (3m) with high lifting speed

- Maximum operating and safety at work

- High availability

- 100% duty cycle

- Low wear

- Easier maintenance through improved accessibility

- High handling rates

Shifting bridges are recommended above the galvanizing area where they allow a rectangular circulation. The driving units move longitudinally on the transfer bridge and are then transported in the transverse direction.

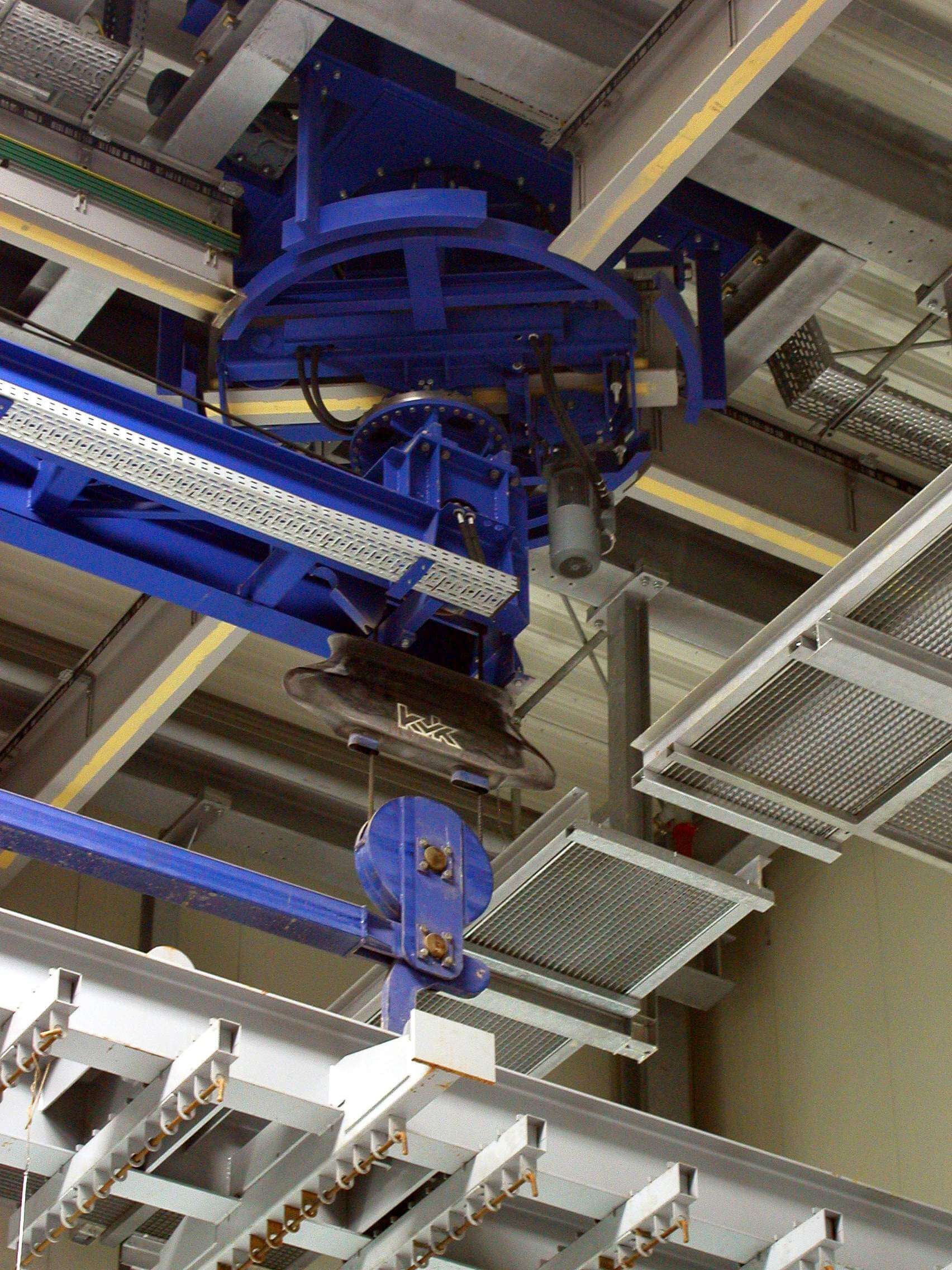

Rotary switches enable a change of direction on moving units and thus the transport of trusses - both in the transverse and in the longitudinal direction. With a change of direction of 90 °, rotary switches enable enormously space-saving installation variants.